Case Study

AMC Bore Hole Stabiliser™ increased metres drilled per day by 40%

Location: Eastern Goldfields of Western Australia

Resource: Au

Application: Underground metallurgic exploration

Objectives

Increasing hole stability to improve metres drilled per day. Find new solutions to replace traditional PVC casing installation.

Challenges

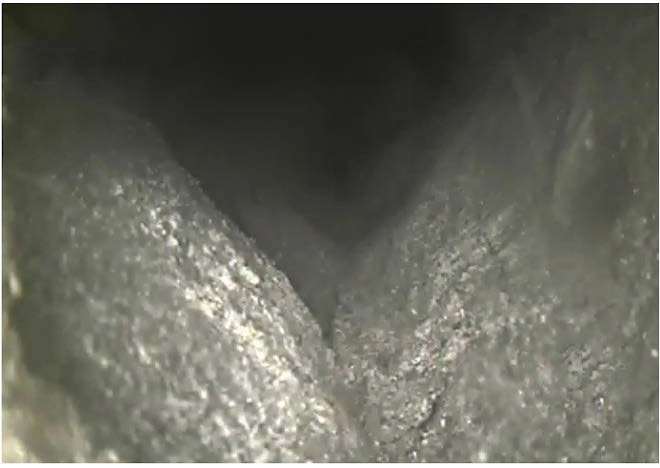

Clusters of Volcanogenic Massive Sulphide (VMS) deposits often resulted in poor hole stability and HSE implications.

Traditional methods of installing PVC casing for explosives loading resulted in lost time for the entire process.

Further complexities of mobilising PVC underground, the HSE risks and blasting inefficiencies made improvements imperative.

IMDEX Solution

AMC Bore Hole Stabiliser System (BHS™)

After initial conversations and analysis, IMDEX suggested trialing the BHS-integrated drilling technology solution on-site to improve productivity and remove the risks and costs associated with installing PVC uphole.

BHS is a multifunctional product formulated to combat a wide range of down hole problems including poor collaring, hole decay and sidewall instability.

The formulation penetrates deep into the surrounding strata, providing lubrication to the hole, increasing lifting capacity for cuttings transportation and encapsulating water sensitive clays or shales.

Strategy & Solution

The BHS drilling technology solution is a proactive additive and delivery system that addresses a wide range of drilling problems including sidewall instability and hole decay, providing a more consistent gauge.

The fluid technology was delivered through an on rig-dosing unit that was integrated into the existing workflow.

BHS has progressed from trial stage to implementation at the site on all production rigs.

.png)

.png)

.png)

.png)