Case Study

AMC BOS™ recovers abandoned hole and boosts productivity

Location: Arizona, USA

Resource: Cu

Project: Resolution Copper's Superior Mine

Application: Borehole recovery

Objectives

Recovering ongoing financial losses, addressing ongoing drilling issues using conventional grouting methods

Challenges

The drilling contractor had spent two weeks trying to advance a drillhole with traditional grouting methods; but due to sloughing and caving around the drilled casing, the crew were unable to advance.

Resolution Copper had battled these issues throughout a 10-year period at the site. The lack of adequate cement seal around the casing was causing ongoing ground control issues as they tried advancing directly from a cut-out of the window wedge down at 2,732 ft.

The hole was also facing formation pressure due to fluids on the outside of the drill casing annular space, further complicated with only 50% fluid returns, and 50% leaking off behind the casing.

As a result of the poor conditions and outcomes of the previous fluid program, the crew had decided to abandon the borehole.

IMDEX Solution

AMC Borehole Optimisation System™ (BOS)

Following a recent successful two-week trial at the site, the Drill Supervisor at Resolution Copper contacted IMDEX about the possibility of using AMC BOS on the troublesome hole to provide a preventative solution to the lost circulation being experienced on-site.

AMC BOS is a proactive solution combating fluid losses and borehole instability, by delivering a measured amount of AMC BOS FIX™ at regular intervals to the bottom of the drill string and up the annulus.

Strategy & Solution

The rapid descent, dual-action, in-hole casing unit delivered a measured amount of AMC BOS FIX™ at regular intervals down the borehole. The AMC BOS UNIT™ deploys BOS FIX at precise locations from the bottom of the drill string into the strata and migrates into the annulus to develop a plasticising membrane on the borehole wall.

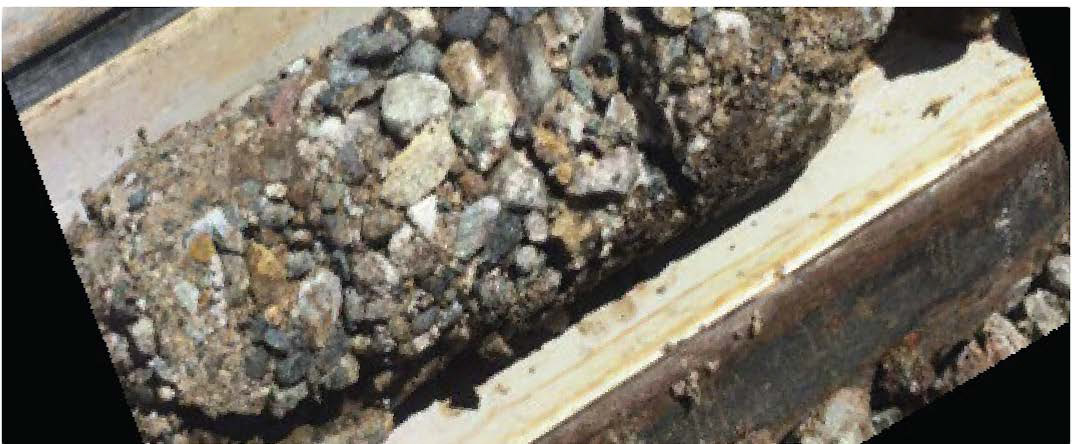

IMDEX injected the hole using the BOS UNIT and conditioned the borehole for 15 minutes before the unit was pulled and the crew started drilling. An initial 1.5' of cave material was recovered, held together by BOS FIX. The biggest challenge facing the drill crew was the low 50% fluid returns, with 50% leaking off behind the casing. Following a second injection, fluid leakage around the casing slowed, and the hole continued to advance an additional 20 ft through the caving and sloughing zones.

BOS was able to stabilise the caving and broken ground, allowing the drill crews to advance the hole a further 93 ft in one shift.

The solution offered a viable and rapid alternative to the conventional method that wasn't producing results.

.png)

.png)

.png)

.png)