Case Study

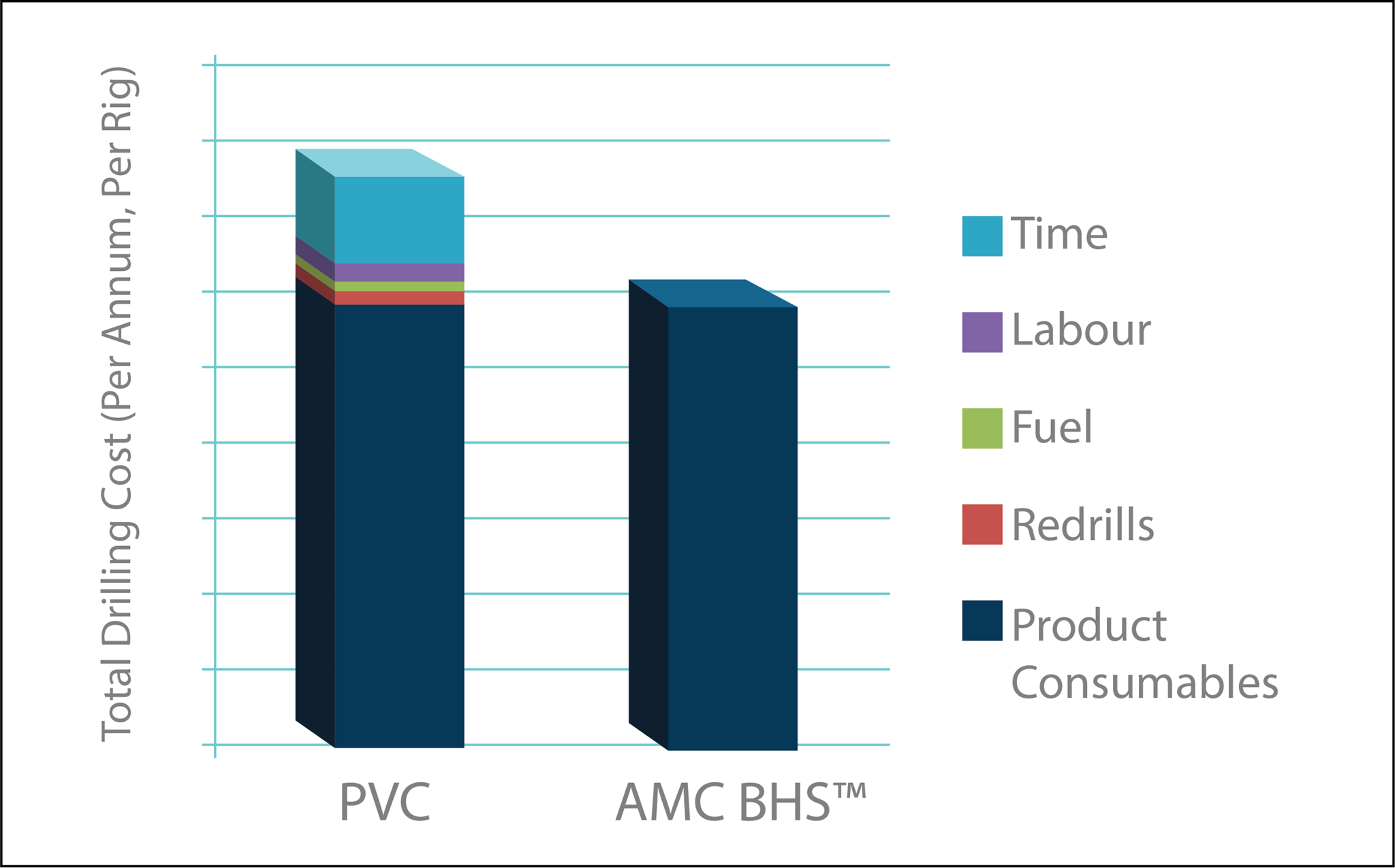

AMC BHS™reduced total drilling costs by 34%

Location: Goldfields region of Western Australia

Resource: Au

Application: Underground metallurgic exploration

Objectives

Increasing hole stability to improve metres drilled per day. Find new solutions to replace traditional PVC casing installation.

Challenges

The underground drill site approximately 20km west of Kalgoorlie, Western Australia, was notorious for shear zones and reactive clays, causing stuck rods while drilling. Geology at the deposit includes a sheared contact zone between the porphyritic 'cat rock' and volcaniclastic rocks of black flag beds.

The operator was frequently experiencing stuck rods - causing issues almost every shift. Up to 31 rods had been lost in one shift, with an approximate total value of $31,000 (AUD$).

The drillers were practicing the traditional method of installing PVC casing to maintain hole stability, but due to the challenging nature of the hole, this method was proving costly and time-consuming. Productivity losses were experienced, rigs stood idle while drill crews manually inserted casing and time was lost through multiple re-drills.

IMDEX Solution

AMC Bore Hole Stabiliser™ (BHS)

BHS is a multifunctional product formulated to combat a wide range of down hole problems including poor collaring, hole decay and sidewall instability. The formulation penetrates deep into the surrounding strata, providing lubrication to the hole, increasing lifting capacity for cuttings transportation and encapsulating water sensitive clays or shales.

Strategy & Solution

BHS was run as a trial of twelve holes - six using BHS and the remaining six using the traditional method of circulating water at full pressure. BHS was injected directly by the 'Fire-Ball 300' pump into the bit face with air and a water mist.

Cameras inserted into each hole to log and compare results confirmed that BHS consolidated the formation, while the water destroyed it by washing it away. During the trial, no hole was compromised using BHS, and no redrills were required.

.png)

.png)

.png)

.png)